PRODUCTS USED

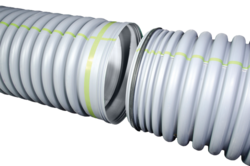

- 23,600’ (7,193 m) of 18” (450 mm) HP Storm Dual Wall Pipe

- 5,780' (1,762 m) of 24" (600 mm) HP Storm Dual Wall Pipe

- 4,880' (1,487 m) of 30" (750 mm) HP Storm Dual Wall Pipe

- 2,480' (756 m) of 36" (900 mm) HP Storm Dual Wall Pipe

The Express Phase 3A-2 project called for watertight joints between sections to meet a 100-year design service life, fit the budget and FDOT requirements, including post-installation inspection.

HP Storm pipe was chosen over reinforced concrete pipe (RCP) due to its superior joint performance, durability, ease of installation and overall cost-effectiveness. Another key factor was the polypropylene pipe is stiffer so it consistently passed the DOT’s mandate that all projects undergo a laser profile inspection that checks for joint gaps, cracks and the pipe’s ovality. If the pipe does not pass the laser profiling, FDOT may require it to be repaired, reinstalled or replaced entirely.

HP Storm passed all of the requirements after installation. The 20’ (6 m) lengths of pipe reduced the number of joints in the pipeline, reduced installation time and increased crew efficiency. Nesting the different pipe diameters reduced truck deliveries and on-site storage space.