| HP Storm Pipe | |

|---|---|

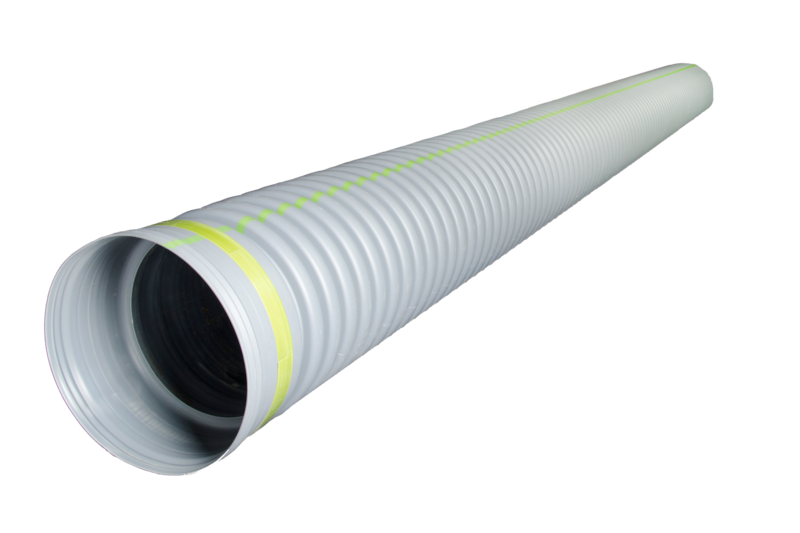

| Diameters Available | 12-60” (300-1500 mm) |

| Lengths Available | 20' (6 m)* |

| Joint Performance | Watertight (ASTM D3212) |

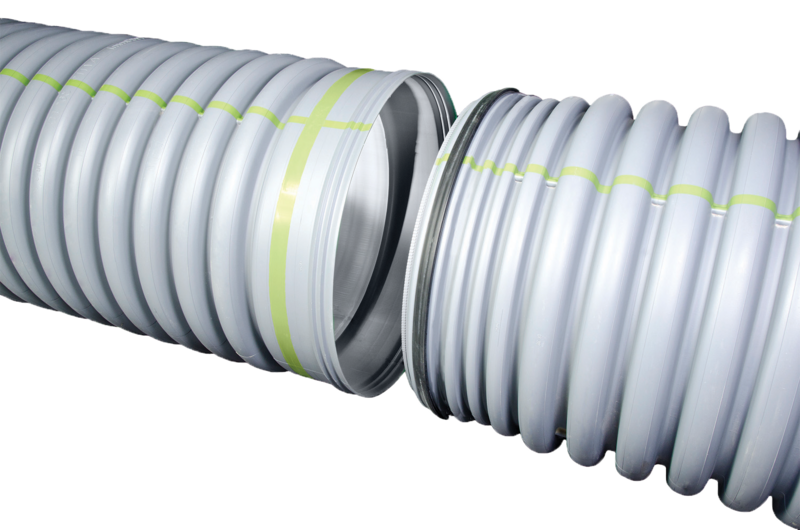

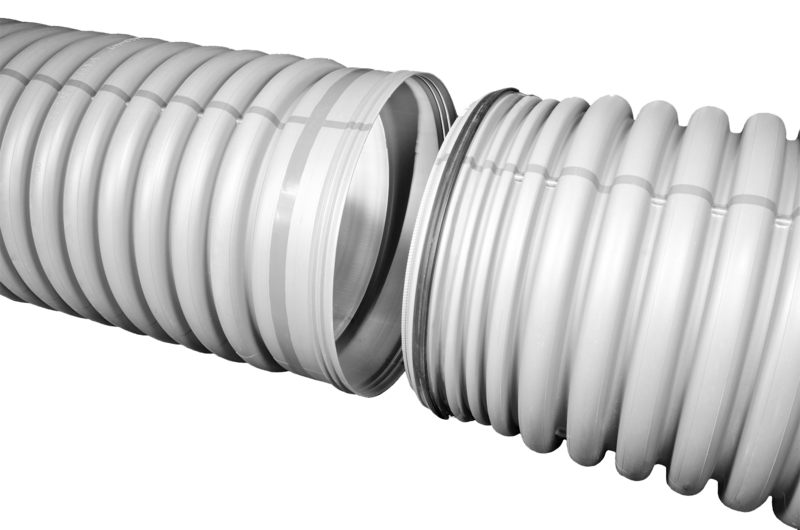

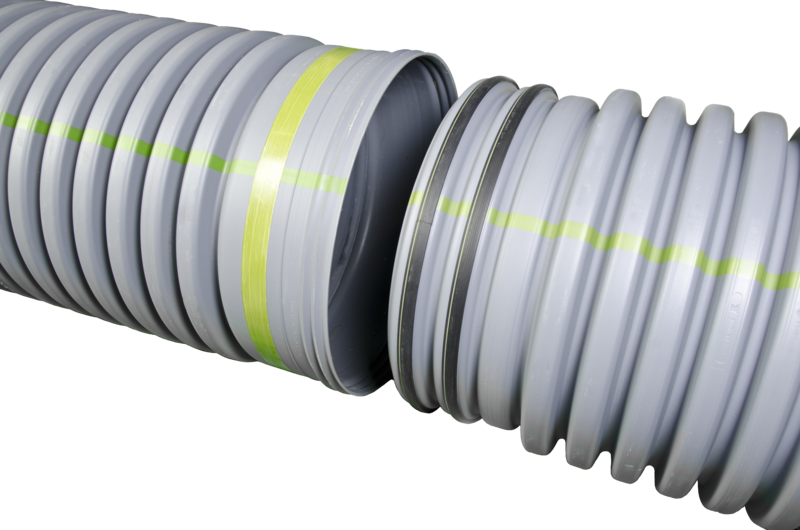

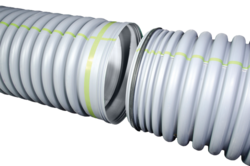

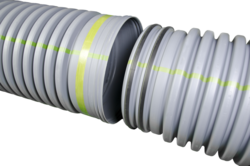

| Joining System | Extended Reinforced Integral Bell & Gasketed Spigot |

| Specifications | AASHTO M330 12-60" (300-1500 mm), ASTM F2881 12-60" (300-1500 mm) |

| Design Service Life | Minimum 100 Year |

*Other lengths available, please contact your sales rep for more details.

Overview

HP Storm offers up to 100 percent greater pipe stiffness over traditional plastic pipe, which increases safety and service life in installations that demand high performance. The extended bell and spigot joint design adds an additional factor of safety within each joint to ensure watertight performance and long term design service life.

HP Storm pipe meets or exceeds ASTM F2881 and AASHTO M330. From a federal perspective, polypropylene (PP) pipe is approved for use by the Army Corps of Engineers for storm drainage applications under Section 33 40 00 (Unified Facilities Guide Specifications). The Federal Aviation Authority (FAA) permits polypropylene pipe under airfield pavements per Item D-701 and as pipe for storm drains and culverts in AC 150/5370-10 current edition. Additionally, the American Railway Engineering and Maintenance-of-Way Association (AREMA) approves polypropylene pipe in storm drainage applications under railroads.

Features and Benefits

- Increased stiffness results in an additional safety factor against construction loading and poor installations

- The extended bell and spigot joint meets ASTM D3212 and ensures lab and field testable watertight performance

- Smooth interior with a Manning's value of 0.012, resulting in increased flow capacity

- Inert PP material is resistant to the effects of chemicals, abrasion, hot soils, and effluent

- Lightweight product for best installed cost to maximize delivery and installation efficiencies

- Readily available in convenient locations to service local projects

Build America, Buy America (BABA) Act

ADS HP Storm pipe, manufactured in accordance with ASTM F2881 or AASHTO M330, complies with the requirements in the Build America, Buy America (BABA) Act.

Documentation

101B Trench Installation (Geotextile Wrap) Detail

101D Trench Installation (HP Storm Pipe) Detail

101E Trench Installation Alternate (HP Storm) Detail

101G Trench Installation (Flowable Fill) Detail

101H Trench Installation Aircraft (HP Storm) Detail

101L PP Trench Installation Detail (CSS)

104A Pipe Anchoring Detail (Geotextile)

104B Pipe Anchoring Detail (Helical and Precast)

107B Railway Trench Installation Detail (PP)

107C Railway Trench Installation Detail (HDPE or PP)

107UD Railway Trench Installation Detail (Underdrain)

111D Minimum Cover Temporary Single Axle HP Pipe Detail

111E Minimum Cover Temporary Tandem Axle HP Pipe Detail

111F Minimum Cover Temporary Tracked Axle HP Pipe Detail

111G Aircraft Landing Gear Footprint (HP Storm) Detail

113 HDPE & PP Connection to Concrete Headwall Detail

114 Concrete Headwall Encased Connection Detail

12"-60" HP per AASHTO M330 Resin Properties Detail

206A 12-60 HP Storm MH Grouted Waterstop Detail

206B 12-30 HP Storm MH Waterstop Cast-in-Place Detail

207A 12-30 HP Storm Compression (Cast-in) Structure Connection with Sleeve or PVC Adapter Detail

207A(EP) 12-24 HP Storm MH Precast Compression Gasket

207B 12-60 HP Storm Booted (Cored or Cast Hole) Structure Connection with Corr Pipe Adapter Gasket Detail

207C 12-30 HP Storm Booted (Cast-in) Structure Connection with Corr Pipe Adapter Gasket Detail

207C(EP) 12-24 HP Storm MH Boot and Fitting

207D 12-30 HP Storm Booted (Cored or Cast Hole) Structure Connection with Sleeve or PVC Adapter Detail

207E 12-30 HP Storm Booted (Cast-in) Structure Connection with Sleeve or PVC Adapter Detail

207F 12-24 HP Storm Booted (Cored or Cast Hole) Structure Connection with Fabricated Adapter

207G 12-24 HP Storm Manhole Booted or Compression (Cast-In) Structure Connection with Fabricate Adapter

402 Installation Catch Basin 8-60in HP Pipe Detail

406 Installation HP Storm Riser Tee 12-24in Pipe Detail

407 Installation HP Storm Riser Tee 30-60in Pipe Detail

48" HP Manhole Installation Detail

604A HP Storm to RCP Connection (MarMac) Detail

705 Retention-Detention (System Installation) Detail

HP Storm Bends Fittings Manual

HP Storm Couplers Fittings Manual

HP Storm Manifolds Fittings Manual

HP Storm Miscellaneous Fittings Manual

ADS Pipe Specification Chart Product Sheet

Golf and Turf Drainage Brochure

HDPE/PP 12" Minimum Cover _ AASHTO LRFD

High Performance Polypropylene Pipe for Slipline Applications Brochure

HP Ag Lift Station Product Sheet

Mar Mac Polyseal Pipe Coupler Product Sheet

N-12 & HP Storm: Corrugated Dual Wall Pipe Comparison

Polypropylene Pipe vs. RCP Comparison Sheet

Potato Pipe Rotation Schedule Sheet

Rainwater Harvesting with HP Pipe Cisterns Product Sheet

Site Development Solutions Brochure

TN 1.01HP HP Storm Perforation Patterns

TN 2.04 Minimum Maximum Cover Heights for HP Storm for Storm Drainage

TN 2.04A Minimum Maximum Cover Heights for Alternate Trench for HP Storm Pipe Trench

TN 4.02 Chemical Resistance of Polypropylene and Elastomers

TN 4.03 Abrasion Resistance of Polypropylene

TN 5.02 Flowable Fill Backfill for Thermoplastic Pipe

TN 5.04 HDPE and HP Storm Connections to Manholes and Structures

TN 5.09 Thermoplastic Pipe and Utility Crossings

TN 5.14 Culvert Sliplining with HP Pipe

TN 5.15 Integral Bell Transition for HP Pipe

TN 5.16 Methods for Sealing Vent Tubes

TN 5.20 Post Installation Testing of HP Storm

TN 6.24 Best Practices for Under-Structure Detention Systems

HP Storm Dual Wall Case Studies

HP Storm Dual Wall Case Studies

Watch how the scale and power of ADS continues to evolve and revolutionize stormwater management.

Case Studies