Frequently Asked Questions

You will find answers to many of our most commonly-asked questions below.

Customer Service FAQs

ADS products are sold through a nationwide network of sales professionals and local distributors. Please contact us with your product needs and we'll put you in touch with a local distributor or salesperson.

To ensure faster, more consistent service, we've updated our Customer Service model. Instead of being routed to one assigned representative, your calls will now go to a dedicated queue. Call us during normal business hours by calling 1-800-821-6710 and our Interactive Voice Response (IVR) system will guide you to the right team.

ADS products are sold through a nationwide network of sales professionals and local distributors. Use our find a rep feature to reach out to your local representative for your project needs.

Use this form to contact your Regional Engineer with any technical questions you have.

Call us at 1-800-821-6710 to order ADS products, ask product-related questions, or receive pricing information.

- Main Menu

- Press 1 – Existing Orders

- Press 2 – Product Availability

- Press 3 – Place a New Order

- If You Press 1: Options for Existing Orders

- Press 1 – Check Order Status

- Press 2 – Revise an Order

- Press 3 – Add Info to an Order

- Press 4 – Report a Credit or Shortage Issue

Call 1-800-821-6710 or email inquiries@adspipe.com.

Opt-in to receive bill of lading copies automatically or call 1-800-821-6710 or email inquiries@adspipe.com.

Reference your order acknowledgement or the latest change confirmation for your order.

Call Customer Service at 1-800-821-6710. When you reach the main menu, press 2 for product availability.

8am-8pm EST

Call 1-800-821-6710 or email inquiries@adspipe.com.

A list of discontinued products are as follows:

Bend-A-Drain, 2” Turf Flow, 12-15” Grain Aire, 6” Smoothwall, Biodiffuser (1100BD, 1101BD, 1122BD, 1500BD, 1501BD, 2200BD), Singlewall Blind Tees (0841AA, 0845AA, 1041AA, 1045AA), StormTech SC-740

Technical FAQs

No. Many native soils are well suited for backfill provided they are compacted properly. These soils meeting the unified soil classifications of a GW, GP, SW, SP (ASTM D-2321 Class II) and GM, GC, SM, SC (ASTM D-2321 Class III)

HDPE pipe is generally less expensive in initial material cost than RCP and less expensive or the same cost as CMP, but the real savings are realized in installed costs. Due to the light weight, longer lay lengths, ease of handling, and push-together joints of ADS pipe, the installed cost savings of HDPE ranges from 10 to 30% when compared to RCP and CMP.

When specifying pipe, the crush strength is a term used for pipes that experience a brittle failure. In other words, the crush strength is the load at which the pipe physically breaks. This is not applicable to a viscoelastic material such as HDPE or an elastic material such as CMP since the material will deflect under load to the point of failure. A HDPE pipe profile can actually deflect until the material is flattened due to reverse curvature. Therefore, an analogous test to crush strength for HDPE pipes would be AASHTO's pipe flattening test, which requires the pipe be deflected 20% with no signs of wall buckling, cracking, splitting, or delamination at a specified pipe stiffness.

There are several methods of connecting dissimilar materials either from ADS or outside companies. The most common method is to butt the two pipes together, wrap the joint with a non-woven geotextile material, and pour a concrete collar around the connection. ADS also offers a spigot adapter that consists of a HDPE cylinder that is welded to the pipe and then slipped into the bell end of the existing pipe. Then, depending on the joint location and performance requirements, a geotextile wrap and/or concrete collar can be employed. Additionally, ADS offers a watertight repair coupler that is wrapped around the joint and tightened with a mechanical coupler. The watertight repair coupler is most effective when used with pipes of similar outside diameters. For additional details on field connections, contact your local ADS representative.

HDPE meeting AASHTO M-252 or M-294 is manufactured with a carbon black coloration that protects the material from UV degradation. Carbon black has been proven to protect exposed HDPE pipe for over three years with no change in tensile properties from UV effects. Once installed, the earth cover protects the pipe from UV effects. Exposed ends of pipes are located in areas of little or no tensile stress (due to no overburden), and therefore not a consideration for UV effects.

Sunlight contains ultra-violet rays that reduce the tensile properties of plastics with time. HDPE pipe installed in the ground is primarily in compression due to the annular profile design of the pipe. Slight tensile stresses in the pipe arising from trench anomalies and residual stresses from the manufacturing process are overcome by the large compressive stresses due to the soil overburden. Therefore, the net stress in the pipe is compressive. Additionally, once the pipe is backfilled it is protected from the effects of UV rays. The pipe's exposed ends are in areas of little or no stress and therefore a reduction in tensile strength due to UV does not affect the pipe's performance. AASHTO and ASTM specifications include requirements of coloration of HDPE pipes with carbon black to inhibit the effects of UV of the material. Carbon black has been proven to protect HDPE pipe for over three years with no change in tensile properties from UV effects. Therefore, when the pipe is stored prior to installation, the carbon black coloration inhibits the effects of UV rays and, once the pipe is installed, it is protected from UV by the backfill materials and exposed ends are located in an area of little or no stress. To illustrate the fact that carbon black protects HDPE from UV degradation, consider the insulation coating on overhead telephone and electric lines. These lines are insulated with HDPE that is continuously exposed. However, since the lines are under relatively low stress, the carbon black coloration protects the lines from UV degradation.

The effects of gasoline and whether the pipe burn will be addressed together since the concern with fuel spills is the potential for a catastrophe, which could damage the pipe. Gasoline does not adversely affect HDPE. The material does not soften or lose strength when exposed to gasoline; however the material will burn if exposed to an outside fuel source (gasoline). When examining the effects of a catastrophic event, one needs to consider the performance of other materials as well as the effects of the event itself. In the case of a fuel spill and a fire in a closed storm drain system, the fire would extinguish itself rather quickly due to an inadequate air supply. Studies have shown that even in an open culvert the fire extinguishes itself within the first few feet of the culvert. Repairs would be relatively simple and involve excavating the ends of the pipe and cutting off the damaged section. This could then be replaced with new pipe.

The Florida DOT conducted a study into the potential damage to HDPE pipes from fire and concluded the risk of a fire was minimal and headwalls would effectively eliminate damage. For a catastrophic event, many commonly used materials would be damaged and require repairs. For example, asphalt pavements would burn, metal pipes (especially asphalt coated) would be damaged and concrete pipes would be weakened due to cracks from expanding aggregate. Therefore, fire has the potential to damage a number of common construction materials. When evaluated from the risk potential of damage, HDPE pipe is no more susceptible to fire damage than other pipe materials.

HDPE offers a very competitive alternative to RCP and CMP. HDPE material costs are generally equal to or less than comparative sizes of RCP and CMP pipes. Due to the low Mannings "n" value of ADS N-12, HDPE pipes are generally one diameter smaller than CMP pipes for equivalent flow characteristics, making HDPE even more cost effective. The inert nature of HDPE and its high abrasion-resistance allow HDPE pipe to be used in environments when RCP and CMP require thicker walls or additional coatings to obtain the required performance. HDPE is manufactured in longer lengths (20') and is significantly lighter than RCP, which equates to faster, safer installation. Finally, ADS N-12 offers a bell and spigot coupler that allows faster installations than CMP. Therefore, considering the competitive cost of ADS N-12 pipe and the savings due to higher performance and faster, safer installations, ADS N-12 is logical alternative to providing cost effective storm drain pipe applications.

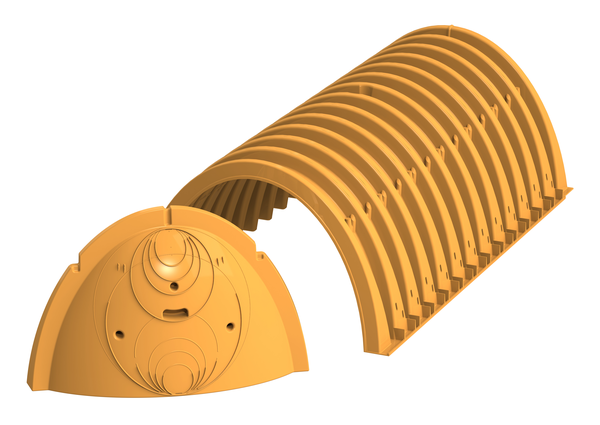

Introducing the EcoPure BioFilter

Introducing the EcoPure BioFilter

This product merges both pretreatment with advanced filtration.

Get to Know EcoPure