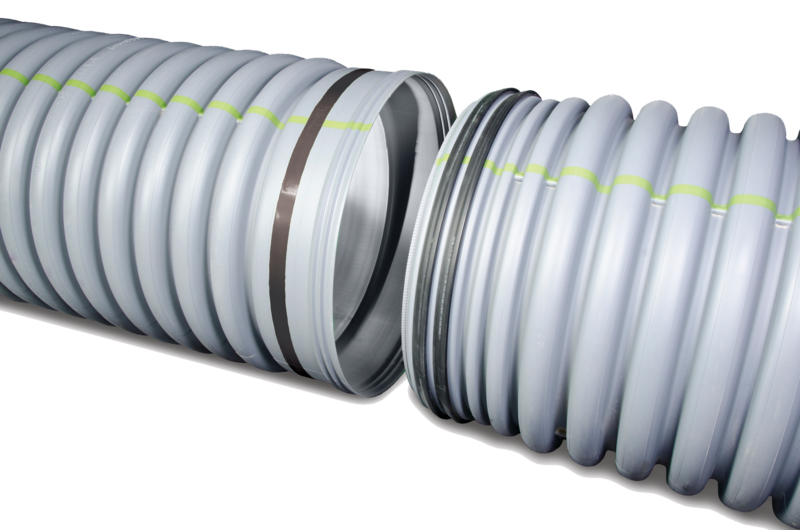

SaniTite® HP Dual Wall Pipe

Featuring advanced polypropylene resin technology, SaniTite HP Dual Wall Pipe (12”- 30”) is the logical choice for gravity flow sanitary sewer pipe. It offers superior joint performance, chemical abrasion, impact resistance, and additional redundancies and factors of safety not received by comparable products.

Product Specifications

| SaniTite HP Dual Wall Pipe |

|---|

| Diameters Available | 12-30" (300-750 mm) |

|---|---|

| Lengths Available | 13', 16.3' & 20' (4.0 m, 4.9 m & 6.1 m)* |

| Joint Performance | Watertight (ASTM D3212 with the addition of a 15 psi pressure requirement) |

| Joining System | Extended Reinforced Integral Bell & Double Gasketed Spigot |

| Specifications | ASTM F2764 12-30" (300-750 mm) and AASHTO M330 12-30" (300-750 mm) |

| Design Service Life | Minimum 100 Year |

| Pipe Stiffness | Minimum 46 pii (ASTM D2412) |

*Other lengths available, please contact your sales rep for more details.

Product Details

Overview

SaniTite is manufactured with enhanced pipe stiffness, beam strength and joint integrity, for a long-lasting life. The bell and spigot joining system provides an added factor of safety for design engineers by including polymer-reinforced bells and double gasket spigots on every stick of pipe.

Features and Benefits

- Increased stiffness yields an additional safety factor against construction loading and poor installations

- The extended bell and spigot joint with redundant, double-gasketed joints meets ASTM D3212 and ensures lab and field testable watertight performance

- 1,000 hour 10.8 psi (74.5 kPa) joint test for 30”-60” (750 mm - 1500 mm) pipe per ASTM F2764

- Meets industry standards for manhole connections, testing and installation

- Inert PP material is resistant to the effects of chemicals, abrasion, hot soils, and caustic effluent

- Lightweight product for best installed cost for maximizing delivery and installation efficiencies

- Readily available in convenient locations to service local projects

ADS SaniTite HP pipe, manufactured in accordance with ASTM F2764, complies with the requirements in the Build America, Buy America (BABA) Act.

Documentation

101B Trench Installation (Geotextile Wrap) Detail

101F Trench Installation (SaniTite HP) Detail

101G Trench Installation (Flowable Fill) Detail

104A Pipe Anchoring Detail (Geotextile)

104B Pipe Anchoring Detail (Helical and Precast)

107B Railway Trench Installation Detail (PP)

107C Railway Trench Installation Detail (HDPE or PP)

110 Lining of Casings Detail (SaniTite HP)

111D Minimum Cover Temporary Single Axle HP Pipe Detail

111E Minimum Cover Temporary Tandem Axle HP Pipe Detail

111F Minimum Cover Temporary Tracked Axle HP Pipe Detail

113 HDPE & PP Connection to Concrete Headwall Detail

12"-60" HP per AASHTO M330 Resin Properties Detail

1300 SaniTite HP Standard Details

205A 12-30 SaniTite HP Compression (Cast-in) Structure Connection with Sleeve or PVC Adapter Detail

205B 30-60 SaniTite HP Compression (Cast-in) Structure Connection Detail

205C 12-30 SaniTite HP Booted (Cored or Cast Hole) Structure Connection with Corr Pipe Adapter Gasket Detail

205D 12-30 SaniTite HP Booted (Cored or Cast Hole) Structure Connection with Sleeve or PVC Adapter Detail

205E 12-30 SaniTite HP Booted (Cast-in) Structure Connection with Sleeve or PVC Adapter Detail

205F 30-60 SaniTite HP Booted (Cored or Cast Hole) Structure Connection Detail

205G 12-24 SaniTite HP Booted (Cored or Cast Hole) Structure Connection with Fabricated Adapter Detail

205H 12-24 SaniTite HP Booted (Cast-in) Structure Connection with Fabricated Adapter Detail

206C 30-60 HP Storm Triplewall MH Waterstop Cast-in-Place Detail

206D 30-60 HP Storm Triplewall MH Grouted Waterstop Detail

208 Connection Drop Manhole 12-24in SaniTite HP Detail

209 Connection Drop Manhole 30-60in SaniTite HP Detail

403 Installation Manhole 48in HP TripleWall Detail

408 Installation SaniTite HP Tee Base with SaniTite HP Riser Less than 13ft Detail

409 Installation SaniTite HP Tee Base with SaniTite HP Riser Less than 20ft Detail

410 Installation SaniTite HP Tee Base with Precast Riser Detail

604B SaniTite HP to RCP Connection (MarMac) Detail

604C SaniTite HP to RCP Connection Water-Tight (MarMac) Detail

606 SaniTite HP to Dissimiliar Pipe Connection Detail

Reducing Plate (Out of Roadway Application) Details

SaniTite HP Bends Fittings Manual

SaniTite HP Couplers Fittings Manual

SaniTite HP Miscellaneous Fittings Manual

SaniTite HP Reducers Fittings Manual

TN 2.05 Minimum Maximum Cover Heights for SaniTite HP for Sanitary Sewer

TN 4.02 Chemical Resistance of Polypropylene and Elastomers

TN 4.03 Abrasion Resistance of Polypropylene

TN 5.02 Flowable Fill Backfill for Thermoplastic Pipe

TN 5.13 SaniTite HP Pipe Repair Options

TN 5.14 Culvert Sliplining with HP Pipe

TN 5.15 Integral Bell Transition for HP Pipe

TN 5.16 Methods for Sealing Vent Tubes

TN 5.17 Post Installation Testing of SaniTite HP

TN 5.18 Lining of Casings with SaniTite HP Pipe

TN 6.24 Best Practices for Under-Structure Detention Systems

Additional Popular Documents

SaniTite HP Dual Wall Case Studies

SaniTite HP Dual Wall Case Studies

Watch how the scale and power of ADS continues to evolve and revolutionize stormwater management.

Case Studies