PRODUCTS USED

- 15,000’ (4,572 m) of 12” (300 mm) SaniTite HP Dual Wall Pipe

- 5,000’ (1,524 m) of 15” (375 mm) SaniTite HP Dual Wall Pipe

- 7,400’ (2,255 m) of 18” (450 mm) SaniTite HP Dual Wall Pipe

- 4,800’ (1,463 m) of 24” (600 mm) SaniTite HP Dual Wall Pipe

- 1,280’ (390 m) of 30” (750 mm) SaniTite HP Triple Wall Pipe

- 1,660’ (506 m) of 36” (900 mm) SaniTite HP Triple Wall Pipe

- 1,800' (548 m) of 48” (1,200 mm) SaniTite HP Triple Wall Pipe

To date this was the largest ADS project ever with MoDOT and aimed to increase highway safety by widening the interstate to reduce bottlenecks and creating innovative interchanges.

The I-270 rehabilitation was named the APWA’s 2024 National Transportation Project of the Year for projects that were $75 million or higher.

Parsons Transportation Group, Horner & Shifrin, Inc., and Millstone Weber, LLC were all part of the project’s design-build team. Since SaniTite HP, a polypropylene pipe, was fully approved by MoDOT in 2013, it is often preferred and specified on St. Louis area projects.

ADS needed to leverage SaniTite HP’s approval longevity and familiarity to be utilized on all aspects of the project, including culverts and stormwater conveyance along the highway. It was beneficial that Horner & Shrifin has previously specified and utilized SaniTite HP and has a strong relationship with the local ADS team.

Horner & Shrifin prefers polypropylene pipe as it is light weight, easy to use and economical. For the I-270 installation, by using 13’ and 20’ (4 and 6 m) sticks of SaniTite HP, Millstone Weber was able to finish the project nearly two months quicker than if they had installed reinforced concrete pipe (RCP), which is made in 8’ (2.4 m) lengths.

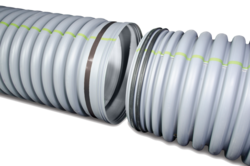

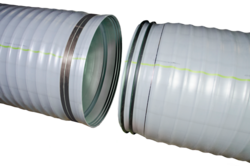

SaniTite HP’s length also meant nearly 3,000 fewer pipe joints are on the project, which increases the system’s overall reliability. In addition, SaniTite HP has dual gaskets and extended bell and spigot for additional safety factors for heavy loading. Installation of the pipe went very well, and it helped that Millstone Weber was familiar with the pipe from previous installations.

The renovated highway’s safety modeling shows the changes are expected to reduce fatal and injury crashes by approximately 15.5 percent. Total vehicular crashes are expected to decrease by approximately 20 percent over 20 years.

The rehabilitation of I-270 went so well, HP Storm, another ADS polypropylene pipe, is now being utilized on MoDOT’s next multi-phase design-build project, “Improve I-70”. This long-term upgrade of I-70 will make the interstate more efficient and safer for the 250-mile (402 km) span across Missouri. There will be eight project segments across the state with total completion scheduled by the end of 2030.