Arc Chambers

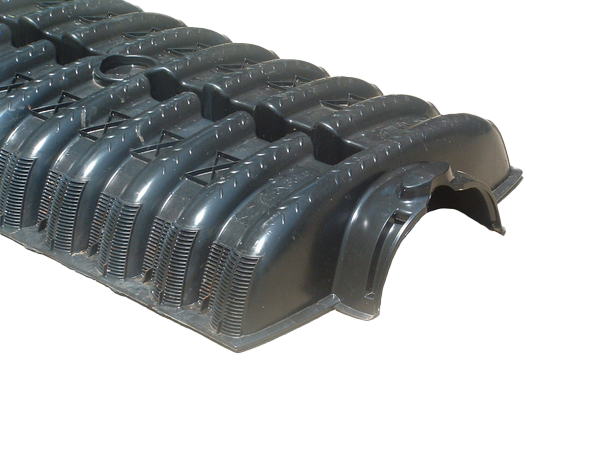

The unique structural design of ARC Chambers makes it able to handle any conventional leachfield system challenge without sacrificing performance. The septic leaching chamber is a sturdy, lightweight polyethylene plastic unit that combines maximized infiltrative surface area and storage capacity. This combination allows for increased effluent dispersal performance and improved structural integrity.

Product Specifications

| ARC Chamber Specifications | |||||

|---|---|---|---|---|---|

| ARC 18 | ARC 24 | ARC 36 | ARC 36 LP | ARC 36 HC | |

| Length | 67" (1.7 m) | 67" (1.7 m) | 63" (1.6 m) | 63" (1.6 m) | 63" (1.6 m) |

| Repeat Length | 60" (1.5 m) | 60" (1.5 m) | 60" (1.5 m) | 60" (1.5 m) | 60" (1.5 m) |

| Sidewall height | 7.5" (19 cm) | 7.5" (19 cm) | 7.13" (18 cm) | 10.75" (27 cm) | |

| Overall Height | 12" (30.5 cm) | 12" (30.5 cm) | 12" (30.5 cm) | 8" (20 cm) | 16" (41 cm) |

| Overall Width | 16" (41 cm) | 22.5" (57 cm) | 34" (86 cm) | 34" (86 cm) | 34.5" (88 cm) |

| Weight | 11 Ibs. | 13 Ibs. | 15 Ibs. | 14 Ibs. | 17 Ibs. |

| Total Open Bottom Area | 6.67 sq ft (.62 sq m) | 7.96 sq ft (.74 sq m) | 11.94 sq ft (1.1 sq m) | 2.44 sq ft (.23 sq m) | 12.27 sq ft (1.1 sq m) |

| Capacity | 3.24 cu ft (.1 cu m) | 5.02 cu ft (.14 cu m) | 8 cu ft (.23 cu m) | 5.80 cu ft (.16 cu m) | 10.7 cu ft (.3 cu m) |

| Pallet Quantity | 180 Chambers | 120 Chambers | 70 Chambers | 70 Chambers | 60 Chambers |

| Van Quantity | 15 Pallets | 17 Pallets | 25 Pallets | 25 Pallets | 25 Pallets |

| Flatbed Quantity | 16 Pallets | 15 Pallets | 22 Pallets | 22 Pallets | 22 Pallets |

Product Details

Overview

The preferred product in leachfield applications, our Arc Chambers are designed to accommodate both gravity-fed and pressure-doses systems with quick installation by one person into trench or bed applications.

These septic leaching chambers are sturdy, lightweight plastic units that combine maximized infiltrative surface area and storage capacity with an improved structural design to handle most any conventional leachfield system challenge without sacrificing performance. This unique combination allows for increased effluent dispersal performance and improved structural integrity as well as ease of installation and simplified contouring capabilities.

Features and Benefits

- Injection–molded from High Density Polyethylene (HDPE) for lightweight and sturdy design

- 20–degree integral articulating joint that is ideal for either straight or contoured septic leachfield applications

- True corrugated chamber design eliminates flat surfaces and provides increased load bearing capability in the trench

- “Lock and Drop” joint provides a more positive connection during installation and backfill

- A universal inlet/outlet end cap

- Inspection vent ports on every unit with easy–to–remove knockouts for maximum job site flexibility

- Convenient five–foot lengths are easy to handle

- Diamond plate texture increases slip resistance and enhances ease of installation

- Side Port Coupler snaps in place to allow side entry at any joint throughout the trench li

Documentation

901 Arc 18 Chamber and End Cap Detail

902 Arc 24 Chamber and End Cap Detail

902A Arc 24 Side Port Coupler Detail

903 Arc 36 Chamber and End Cap Detail

903A Arc 36 Side Port Coupler Detail

904 Arc 36 HC Chamber and End Cap Detail

904A Arc 36 HC Side Port Coupler Detail

905B Arc 24 Trench Installation Detail

905C Arc 36 Trench Installation Detail

905D Arc 36 HC Trench Installation Detail

905E Arc 36 LP Trench Installation Detail

906A Arc 18 Serial Installation Detail

906B Arc 24 Serial Installation Detail

906C Arc 36 Serial Installation Detail

906D Arc 36 HC Serial Installation Detail

906E Arc 36 LP Serial Installation Detail

907A Arc 18 Cluster Installation Detail

907B Arc 24 Cluster Installation Detail

907C Arc 36 Cluster Installation Detail

907D Arc 36 HC Cluster Installation Detail

907E Arc 36 LP Cluster Installation Detail

908A Arc 18 At Grade Installation Detail

908B Arc 24 At Grade Installation Detail

908C Arc 36 At Grade Installation Detail

908D Arc 36 HC At Grade Installation Detail

908E Arc 36 LP At Grade Installation Detail

909A Biodiffuser Product Details

910 Arc Side Port Coupler Serial Distribution Detail

910A 11in Biodiffuser Trench Installation Detail

910B 16in Hi Capacity Biodiffuser Trench Installation Detail

910C Bio 2 Biodiffuser Trench Installation Detail

910D Bio 3 Biodiffuser Trench Installation Detail

911 Arc Side Port Coupler Center Feed Detail

911A 11in Biodiffuser Serial Installation Detail

911B 16in Hi Capacity Biodiffuser Serial Installation Detail

911C Bio 2 Biodiffuser Serial Installation Detail

See our Case Studies

See our Case Studies

Watch how the scale and power of ADS continues to evolve and revolutionize stormwater management.

Case Studies