ADS HDPE Pipe shows outstanding performance under 315,000 pound rail cars Product Sheet

Filename:

ADS HDPE Pipe shows outstanding performance under 315,000 pound rail cars Product Sheet.pdf

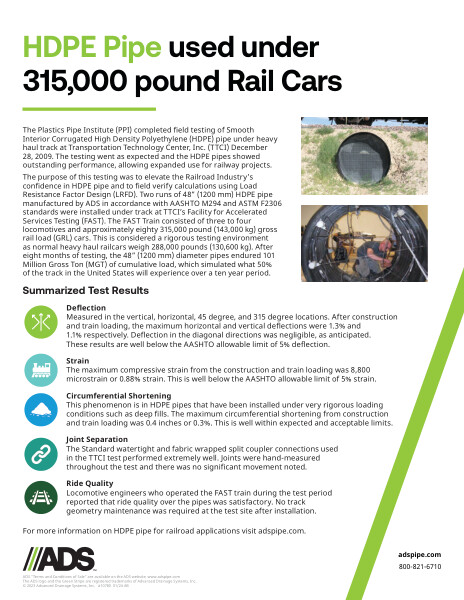

The Plastics Pipe Institute (PPI) completed field testing of Smooth Interior Corrugated High Density Polyethylene (HDPE) pipe under heavy haul track at Transportation Technology Center, Inc. (TTCI).

The testing proved that HDPE pipes provide outstanding performance, allowing expanded use for railway projects. The purpose of this testing was to elevate the Railroad Industry’s confidence in HDPE pipe and to field verify calculations using Load Resistance Factor Design (LRFD).

Two runs of 48” HDPE pipe manufactured by ADS in accordance with AASHTO M294 and ASTM F2306 standards were installed under track at TTCI’s Facility for Accelerated Services Testing (FAST). The FAST Train consisted of three to four locomotives and approximately eighty 315,000-pound gross rail load (GRL) cars. This is considered a rigorous testing environment as normal heavy haul rail cars weigh 288,000 pounds. After eight months of testing, the 48” diameter pipes endured 101 Million Gross Ton (MGT) of cumulative load, which simulated what 50% of the track in the United States will experience over a ten year period.

A summary of the test results show that after construction and train loading, the maximum horizontal and vertical deflections were 1.3% and 1.1% respectively. Deflection in the diagonal directions was negligible. These results are well below the AASHTO allowable limit of 5% deflection.

The test result for strain showed that the maximum compressive strain from the construction and train loading was 8,800 microstrain or 0.88% strain. This is well below the AASHTO allowable limit of 5% strain.

The test result for circumferential shortening showed that the maximum circumferential shortening from construction and train loading was 0.4 inch or 0.3%, well within expected and acceptable limits.

The test result for joint separation showed that the Standard watertight and fabric wrapped split coupler connections used in the TTCI test performed extremely well. Joints were hand-measured throughout the test and there was no significant movement noted.

The test result for ride quality indicated that the locomotive engineers who operated the FAST train during the testing period reported that ride quality over the pipes was satisfactory. No track geometry maintenance was required at the test site after installation.