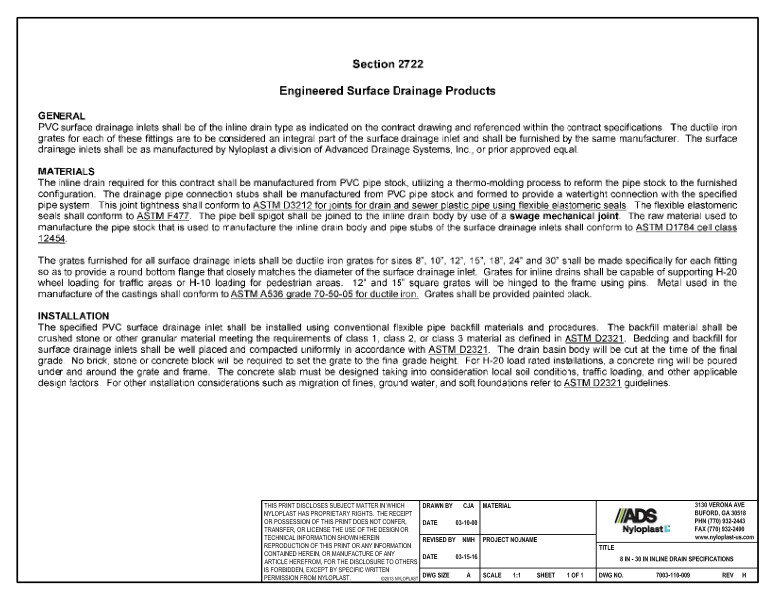

8" - 30" Inline Drain Specifications Nyloplast Detail

Filename:

8" - 30" Inline Drain Specifications Nyloplast Detail.dwg

This document is the 8" - 30" Inline Drain Specifications Nyloplast Detail. Engineered surface drainage products are highlighted.

Generally, PVC surface drainage inlets shall be the inlet drain type specified in the plan. The ductile iron grates for each of these fittings are integral to the surface drainage inlet and be furnished by the Nyloplast, a division of ADS.

The materials for the inline drain are manufactured from PVC pipe utilizing a thermo-molding=g process to reform the pipe stock into the furnished configuration. The drainage pipe connection stubs are made from PVC pipe stock and formed to provide a watertight connection per ASTM D3212. The flexile elastomeric seals conform to ASTM F477. The pipe bell spigot is joined to the inline drain body using a SWAGE mechanical joint. The grates shall be ductile iron specifically made for each fitting to provide a round bottom flange that matches the surface drainage inlet diameter. 12” and 15” square grates will be hinged to the frame using pins. Grates will be painted black.

Installation of the PVC surface drainage inlet uses conventional flexible pipe backfill materials and procedures. The backfill material shall be crushed stone or other granular material. Bedding and backfill shall be well placed and compacted uniformly. The drain basin body will be cut at final grade. No brick, stone or concrete black is required to set grate to final height. For H-20 installations, a concrete ring will be poured under and around the grate and frame. The concrete slab must be designed per local soil conditions, traffic loading and other design factors.