TN 5.13 SaniTite HP Pipe Repair Options

Filename:

TN 5.13 SaniTite HP Pipe Repair Options.pdf

This document is the TN 5.13 SaniTite HP Pipe Repair Options. External mechanical repairs and internal repairs discussed. Diagrams included.

ADS SaniTite HP for sanitary sewer is made of polypropylene (PP) resin making the pipe lightweight and very easy to handle. The attributes that make the pipe easy to use can also make it susceptible to abuse, possibly resulting in damaged pipe or joints.

This technical note discusses some of the products available that can be used to repair damaged PP pipe or joints in the field.

One of the primary considerations in selecting a repair method is the degree of joint performance required. For sanitary sewer applications, a watertight repair is always necessary in contrast to storm drain repairs that may have a less stringent joint performance. A commonly accepted industry maximum allowance specified for infiltration/exfiltration acceptance for sanitary pipelines is 200 gal/in-diam./mile of sewer/day, though regional specifications may vary and be as stringent as 50 gal/in-diam./mile of sewer/day. The way in which a pipe can be accessed is another primary consideration which influences what type of repair alternative is selected. Pipe that is not yet buried, or can be easily excavated, can be repaired from the exterior. If the pipe is buried and cannot be conveniently excavated, an internal repair may be the best alternative. If the pipe is too small to enter, there are companies with remote controlled equipment that can install the product. Each situation must be considered individually.

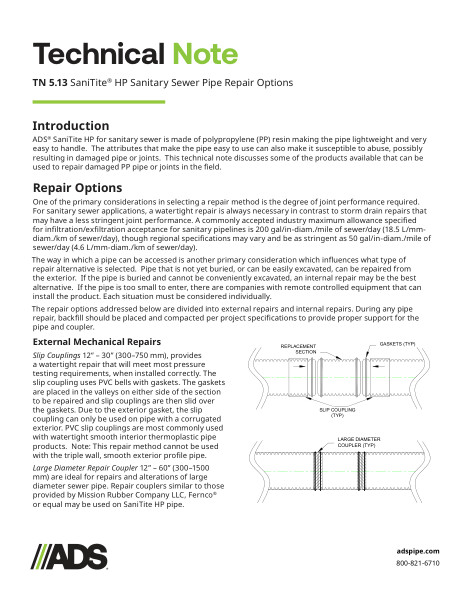

External mechanical repair options explained are slip couplings, large diameter repair coupler and concrete collars. Diagrams show each option.

Internal mechanical repair products generally consist of a flexible cylindrical gasket sleeve, which is expanded to conform to the inner wall of the pipe. The feasibility of this repair method depends on the size of the damaged section or joint and available access into the pipe. Internal mechanical seals slightly restrict the inside diameter of the pipe. This should be considered when assessing the risk of debris obstruction.

Internal mechanical repair options explained are NPC internal joint seal, welding, link pipe grouting sleeve and internal chemical sealing.