TN 5.06 Culvert Sliplining with HDPE Pipe

Filename:

TN 5.06 Culvert Sliplining with HDPE Pipe.pdf

This document is the TN 5.06 Culvert Sliplining with HDPE Pipe. It explains structural requirements and installation for HP pipe products.

An abrasive or corrosive environment can cause premature deterioration of some types of pipe. In lieu of a total replacement, sliplining the existing pipe with a durable material may be an economical method to significantly extend the service life. Polyethylene pipe, because of its resistance to aggressive environments, is often the product of choice to slipline deteriorated pipes. This technical bulletin describes the site and installation considerations that must be evaluated before using HDPE pipe in these applications.

ADS HP pipe products have an integral bell which maintains a constant pipe outside diameter (OD). This constant OD eliminates the need for bell holes and makes it easier to maintain line and grade during installation. The bell and spigot design for HP products, with an elastomeric rubber gasket meeting ASTM F477, meets or exceeds the watertight testing requirements outlined in ASTM D 3212.

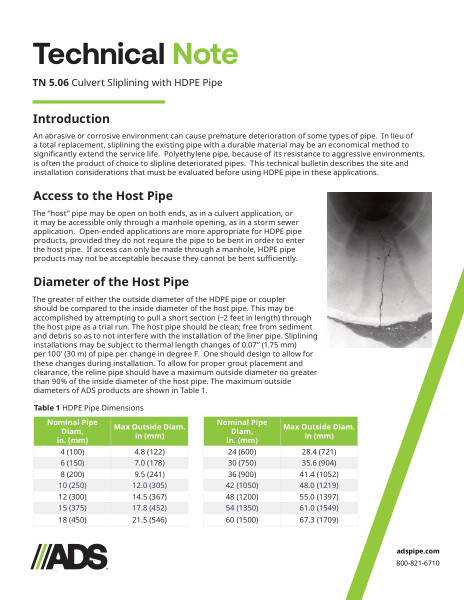

The diameter of the Host Pipe is determined by the greater of either the outside diameter of the HDPE pipe or coupler compared to the inside diameter of the host pipe. A table for HDPE pipe dimensions is shown.

Length of installation and hydraulic considerations are explained.

Structural Requirements discusses failing culverts in need of relining may eventually deteriorate into a conduit with no structural integrity at all. For this reason, it is important to reline with a culvert capable of handling the loads based on its installation assuming no load reduction from the host pipe.

Loading for Highway and pavement tunnels shall be based upon a continuous load carrying structure for the height of cover under HS-25 loading.

Installation of HDPE in host pipe starts before the HDPE pipe is inserted into an existing culvert for relining, it is critical to inspect the existing culvert for any objects or obstructions, which may be extending into the barrel of the existing culvert to be relined. Failure to do this may result in a damaged reline.

Processes for insertion forces and grouting procedures with photographs is included.