Injection Molded Fitting Specification

Filename:

Injection Molded Fitting Specification.pdf

This document is the Injection Molded Fitting Specification. Scope, fitting requirements and material properties with various fittings figures included.

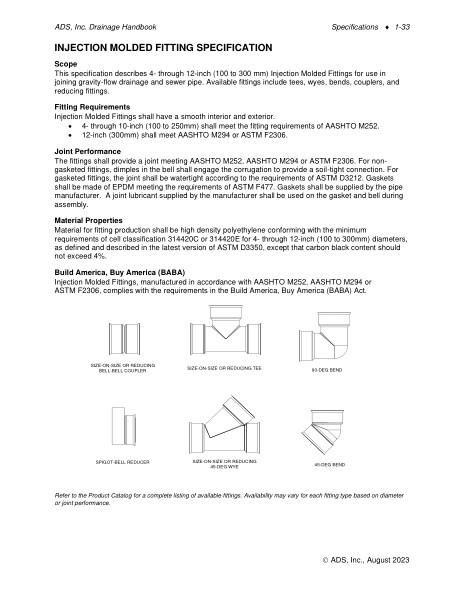

This specification describes 4- through 12-inch (100 to 300 mm) ADS Injection Molded Fittings for use in joining gravity-flow drainage and sewer pipe. Available fittings include tees, wyes, bends, couplers, and reducing fittings.

ADS Injection Molded Fittings shall have a smooth interior and exterior. 4- through 10-inch (100 to 250mm) shall meet the fitting requirements of AASHTO M252. 12-inch (300mm) shall meet AASHTO M294 or ASTM F2306.

The fittings shall provide a joint meeting AASHTO M252, AASHTO M294 or ASTM F2306. For non-gasketed fittings, dimples in the bell shall engage the corrugation to provide a soil-tight connection. For gasketed fittings, the joint shall be watertight according to the requirements of ASTM D3212. Gaskets shall be made of EPDM meeting the requirements of ASTM F477. Gaskets shall be supplied by the pipe manufacturer. A joint lubricant supplied by the manufacturer shall be used on the gasket and bell during assembly.

Material for fitting production shall be high density polyethylene conforming with the minimum requirements of cell classification 314420C or 314420E for 4- through 12-inch (100 to 300mm) diameters, as defined and described in the latest version of ASTM D3350, except that carbon black content should not exceed 4%.

ADS Injection Molded Fittings, manufactured in accordance with AASHTO M252, AASHTO M294 or ASTM F2306, complies with the requirements in the Build America, Buy America (BABA) Act.

Figures shown are size-on-size or reducing bell-bell coupler, size-on-size or reducing Tee, 90 degree bend, spigot-bell reducer, size-on-size or reducing 45 degree wye and 45 degree bend. An injection molded fittings joint system figures are also provided.