N-12 ST IB (ASTM F2648) Specification

Filename:

N-12 ST IB (ASTM F2648) Specification.pdf

The ADS® N-12® ST IB (per ASTM F2648) specification covers pipe requirements, joint performance, fittings, material properties, installation information & BABA information for this product.

Pipe requirements for the N-12 ST IB (per ASTM F2648) include a smooth interior and annular exterior corrugations, 4”-60” (100 to 1550 mm) pipe shall meet ASTM F2648 , and Manning’s “n” value for use in design shall be 0.012.

Pipe shall be joined using a bell & spigot joint meeting ASTM F2648. The joint shall be soil tight and gaskets for diameters 12”- 60”, shall meet the requirements of ASTM F477. For diameters 4”-10”, the joint shall be soil tight using an engaging dimple connection. Gaskets shall be installed by the pipe manufacturer and covered with a removable, protective wrap to ensure the gasket is free from debris. A joint lubricant available from the manufacturer shall be used on the gasket and bell during assembly.

Fittings need to conform to ASTM F2306. Bell and spigot connections will utilize a welded bell and valley or saddle gasket meeting the soil tight joint performance requirements of ASTM F2306.

Material for pipe production shall be an engineered compound of virgin and recycled high density polyethylene conforming with the minimum requirements of cell classification 424420C (ESCR Test Condition B) for 4”-10” (100 to 250 mm) diameters, and 435420C (ESCR Test Condition B) for 12- through 60-inch (300 to 1500 mm) diameters, as defined and described in the latest version of ASTM D3350, except that carbon black content should not exceed 4%. The design engineer shall verify compatibility with the overall system including structural, hydraulic, material, and installation requirements for a given application.

Installation is in accordance with ASTM D2321 and ADS recommended installation guidelines, with the exception that minimum cover in trafficked areas for 4”-48”(100 to 1200 mm) diameters shall be one foot. (0.3 m) and for 60” (1500 mm) diameter the minimum cover shall be 2 ft. (0.6 m) in single run

applications. Backfill for minimum cover situations shall consist of Class 1 (compacted), Class 2 (minimum 90% SPD) or Class 3 (minimum 95% SPD) material. Maximum fill heights depend on embedment material and compaction level; please refer to Technical Note 2.01.

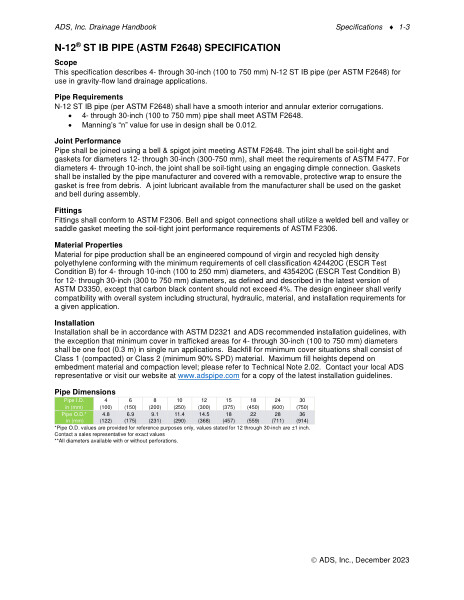

A Pipe Dimensions table is included for reference.