107C Railway Trench Installation Detail (HDPE or PP)

Filename:

107C Railway Trench Installation Detail (HDPE or PP).dwg

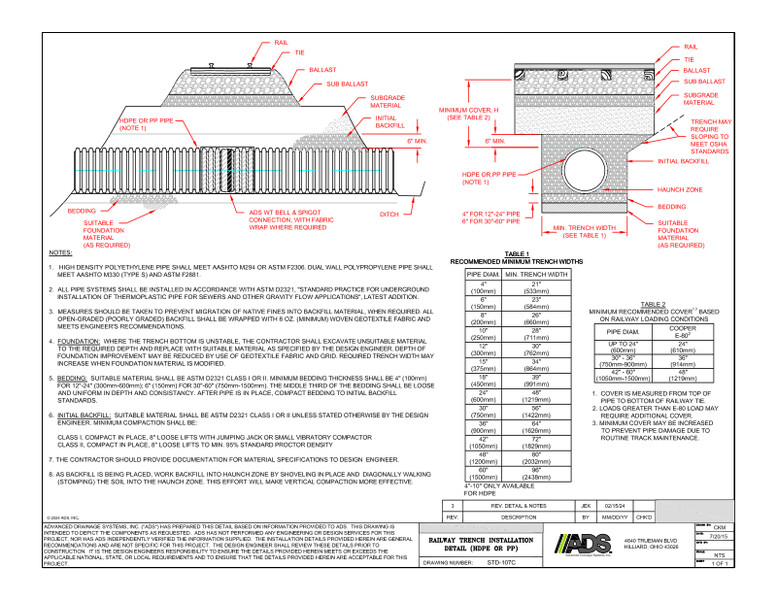

This document is the drawing for the 107C Railway Trench Installation Detail (HDPE) showing how to install HDPE or PP pipe under a railway..

The 107C Railway Trench Installation provides 2 drawings, both front and side view. The drawings illustrate installation from the top, starting with the rails, the ties, the ballast and the sub ballast. Underneath that is the subgrade material with the initial backfill. For the pipe joints, use a split band coupler and fabric wrap (use WT IB pipe when a watertight joint is required). The side view drawing indicates that the trench may require sloping to meet OSHA standards. Please refer to the drawing for bedding measurements and minimum trench widths.

This drawing includes installation notes. Note 1 states that high density polyethylene pipe has to meet AASHTO M294 or ASTM F2306. Dual wall polypropylene pipe has to meet AASHTO M330 (Type S), ASTM F2736 and ASTM D2881. Triple wall polypropylene pipe needs to meet AASHTO M330 (Type D) and ASTM F2764.

Note 2 says that all pipe systems shall be installed in accordance with ASTM D2321, “Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and other Gravity Flow Applications.”

Note 3 says measures should be taken to prevent migration of native fines into backfill material, when required. All open-graded (poorly graded) backfill shall be wrapped with a minimum 8 oz. woven geotextile fabric.

Note 4 is about the foundation. Where the trench bottom is unstable, the contractor will excavate unsuitable material to the required depth and replace it with suitable material as specified.

Note 5 covers bedding requirements. Suitable materials need to be ASTM Class I, II, or III. Minimum bedding thickness for 4” (100mm) is 12”-24” (300mm-600mm). Minimum bedding thickness for 6” (150mm) for 30”-60” (750mm-1500mm). The middle third of the bedding shall be loose and uniform in depth and consistency. See the drawing for more information and additional notes.

Two tables are also provided for reference. Table 1 is the Recommended Minimum Trench Widths with Pipe Diameters and Minimum Trench Widths. Table 2 is the Minimum Recommended Cover Based on Railway Loading Conditions with Pipe Diameter and Cover. Refer to the drawing for more information.