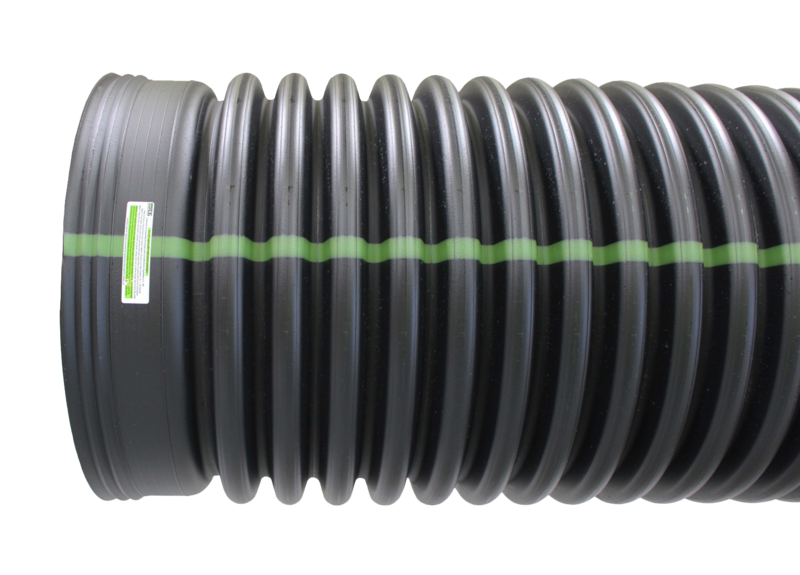

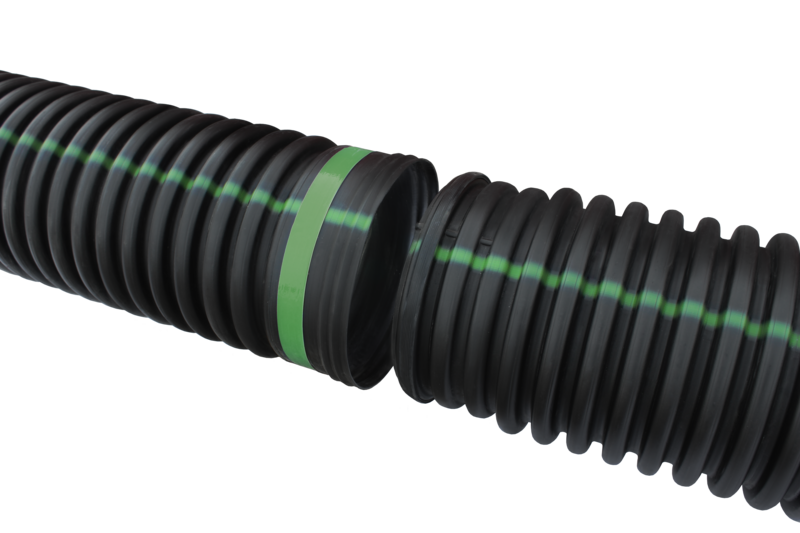

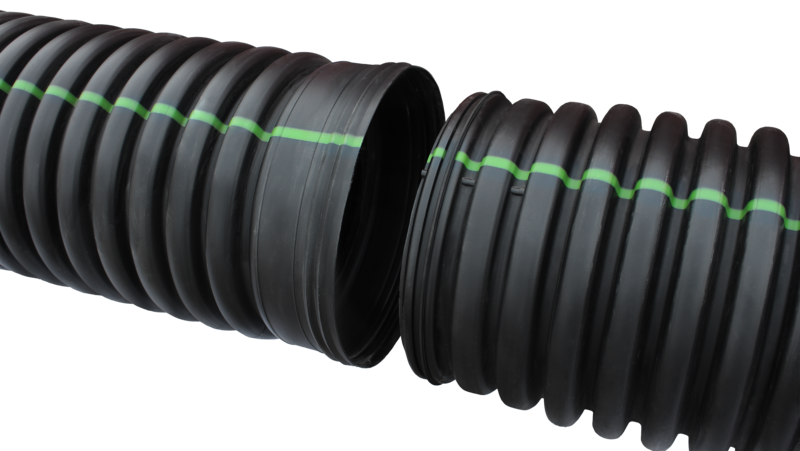

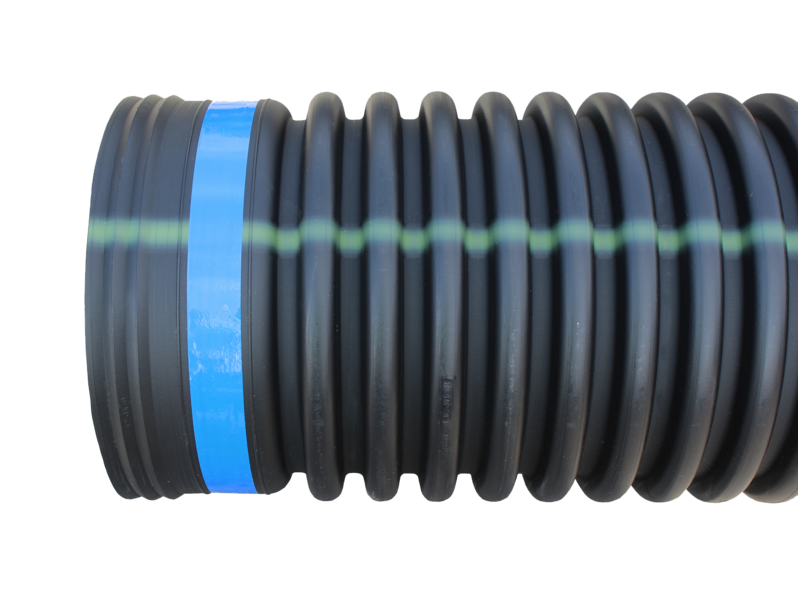

N-12 Dual Wall Pipe

| Plain End | Soil Tight (STIB) | Watertight (WTIB) | |

|---|---|---|---|

| Diameters Available | 4-60" (100-1500 mm) | 4-30" (100-750 mm) | 4-60" (100-1500 mm) |

| Lengths Available | 13', 20' (4, 6 m) | 13', 20' (4, 6 m) | 13', 20' (4, 6 m) |

| Joint Performance | Soil Tight | Soil Tight | Watertight (ASTM D3212) |

| Joining System | External Coupler | Integral Bell & Gasketed Spigot |

Watertight Reinforced Integral Bell & Gasketed Spigot |

| Specifications |

AASHTO M252 - 4-10" (100-250 mm) AASHTO M294 - 12-60" (300-1500 mm) ASTM F2306 - 12-60" (300-1500 mm) ASTM F2648 - 4-60" (100-1500 mm) |

AASHTO M252 - 4-10" (100-250 mm) AASHTO M294 - 12-30" (300-750 mm) ASTM F2306 - 12-30" (300-750 mm) ASTM F2648 - 4-30" (100-750 mm) |

AASHTO M252 - 4-10" (100-250 mm) AASHTO M294 - 12-60" (300-1500 mm) ASTM F2306 - 12-60" (300-1500 mm) ASTM F2648 - 4-60" (100-1500 mm) |

| Design Service Life | Minimum 100 Year | Minimum 100 Year | Minimum 100 Year |

Overview

N-12 pipe is available in soil tight (ST), water tight (WT) and plain end, all of which offer joint options of bell and spigot design, gasket, bell wrap or pressure-rated 10.8 psi coupler. It's available with multiple joining systems, and provides corrugated-pipe strength and smooth interior wall hydraulics for increased flow capacity, in a lifetime package.

Build America, Buy America (BABA) Act

These products, manufactured in accordance with AASHTO M252, AASHTO M294 or ASTM F2306, complies with the requirements in the Build America, Buy America (BABA) Act.

- N-12 Per AASHTO

- N-12 WT Series 35

- N-12 Low Head

Features and Benefits

- Smooth interior with a Manning's value of 0.012 resulting in increased flow capacity

- Inert HDPE material is resistant to the effects of chemicals, abrasion, hot soils, and effluent

- Lightweight product for best-installed cost and maximizing delivery and installation efficiencies

- Structurally designed corrugated exterior to support typical construction and long term loading

- Readily available in convenient locations to service local projects

- Joint options to meet your application performance requirements, including up to water-tight joints meeting ASTM D3212

- Available in ST, WT and Plain End

- Joint options include bell and spigot design, gasket, bell wrap or pressure-rated 10.8 psi coupler

Lubricants

- Soft, paste like compound

- High performance pipe joint lubricant

- NSF certified for potable water pipelines

- Contains no petroleum-Will not swell gaskets

- Stable from -10 to 120°F

- Non-toxic

- No objectionable odor

- Will not support bacteria

- Effect on gaskets-less than 1% weight gain and less than 1 duro hardness loss

- Effectively lubricates pipe and pipe gaskets for safe and efficient assembly

Ask your sales representative for more information on these and other ADS products.

Documentation

10"-36" Double Wide ST Coupler (HDPE Dual Wall Couplers Fittings)

10"-60" "H" Profile ST Split Coupler (HDPE Dual Wall Couplers Fittings)

101 Trench Installation (N-12 per AASHTO) Detail

101A Trench Installation (ASTM F2648) Detail

101B Trench Installation (Geotextile Wrap) Detail

101C Trench Installation (Perf Pipe) Detail

101G Trench Installation (Flowable Fill) Detail

101K HDPE Trench Installation Detail (CSS)

101P Trench Installation Aircraft (N-12) Detail

104A Pipe Anchoring Detail (Geotextile)

104B Pipe Anchoring Detail (Helical and Precast)

106A French Drain Detail (Perf HDPE)

107A Railway Trench Installation Detail (HDPE)

107C Railway Trench Installation Detail (HDPE or PP)

107UD Railway Trench Installation Detail (Underdrain)

111A Minimum Cover Temporary Single Axle HDPE Pipe Detail

111B Minimum Cover Temporary Tandem Axle HDPE Pipe Detail

111C Minimum Cover Temporary Tracked Axle HDPE Pipe Detail

111H Aircraft Landing Gear Footprint (N-12) Detail

113 HDPE & PP Connection to Concrete Headwall Detail

114 Concrete Headwall Encased Connection Detail

12"-60" End Caps (HDPE Dual Wall End Caps & Plugs Fittings)

12"-60" HDPE per AASHTO Resin Properties Detail

12"-60" HDPE per ASTM F2648 Resin Properties Detail

1201 Green Layout Installation (Perf HDPE) Detail

1203 USGA Green Profile (Perf HDPE) Detail

1205 USGA Sand Green Profile (Perf HDPE) Detail

1207 USGA Tee Profile (Perf HDPE) Detail

1209 USGA Bunker Drainage Profile Sand Trap (Perf HDPE) Detail

1210 USGA Bunker Drainage Profile Grass (Perf HDPE) Detail

202 12-60 HDPE PP Soil-Tight Grouted MH Connection

202A Connection Soil-Tight MH Nyloplast Adapt 12-24in HDPE Detail

203 Connection MH Grouted Waterstop 12-60in HDPE Detail

204A 12-60 HDPE N-12 Compression (Cast-in) Structure Connection Detail

204B 12-42 HDPE N-12 Booted (Cored or Cast Hole) Structure Connection Detail

204C 12-30 HDPE N-12 Compression (Cast-in) Structure Connection with PVC Adapter Detail

204D 12-36 HDPE N-12 Z-LOK Booted (Cast-in) Structure Connection Detail

204E 12-60 HDPE N-12 Booted (Cored or Cast Hole) Structure Connection with Corr Pipe Adapter Gasket Detail

204F 12-30 HDPE N-12 Booted (Cast-in) Structure Connection with Corr Pipe Adapter Gasket Detail

204G 12-30 HDPE N-12 Booted or Cast Hole) Structure Connection with PVC Adapter

204H 12-30 HDPE N-12 Booted (Cast-In) Structure Connection with PVC Adapter

36"-60" Split Coupler Reference Chart (HDPE Dual Wall Couplers Fittings)

4"-10" HDPE per AASHTO Resin Properties Detail

4"-10" HDPE per ASTM F2648 Resin Properties Detail

4"-24" External Snap Coupling (HDPE Dual Wall Couplers Fittings)

4"-60" Diameter End Plugs (HDPE End Plugs and Plugs Fittings)

401 Installation Catch Basin 8-60in HDPE Pipe Detail

404 Installation HDPE Riser Tee 12-24in Detail

405 Installation HDPE Riser Tee 30-60in Detail

48" Hybrid Split Coupler (HDPE Dual Wall Couplers Fittings)

6" - 10" Diameter Dual Wall Snap End Cap (HDPE End Caps and Plugs)

6"-60" "A" Profile ST Split Coupler (HDPE Dual Wall Couplers Fittings)

601 HDPE to CMP Connection (Geotextile Wrap) Detail

602 HDPE to CMP Connection (MarMac) Detail

603 HDPE to RCP Connection (Geotextile Wrap) Detail

604 HDPE to RCP Connection (MarMac) Detail

605 HDPE to RCP Connection (Bell Connection) Detail

607 HDPE to HDPE Connection Detail

608 HDPE to HDPE Connection (MarMac) Detail

609 HDPE Plain End to RCP Plain End Connection (MarMac) Detail

701 Retention-Detention System (Plan View) Detail

702 Retention-Detention System (Cross-Section) Detail

703 Retention-Detention System (Riser and Cleanout) Detail

705 Retention-Detention (System Installation) Detail

8"-24" Split End Caps (HDPE Dual Wall End Caps & Plugs Fittings)

HDPE Dual Wall End Caps & Plugs Fittings Manual

HDPE Dual Wall Fabricated Bends Fittings Manual

HDPE Dual Wall Fabricated Reducers Fittings Manual

HDPE Dual Wall Fabricated Tees Fittings Manual

HDPE Dual Wall Miscellaneous Fittings Manual

STD 101I - Inserta Tee® Fitting for ADS HDPE Mainline Detail

ADS HDPE Pipe shows outstanding performance under 315,000 pound rail cars Product Sheet

ADS Pipe Specification Chart Product Sheet

Commercial & Residential Drainage Brochure

Engineered Drainage for Railway Applications

Fine Slot N-12 Pipe Product Sheet

Golf and Turf Drainage Brochure

HDPE/PP 12" Minimum Cover _ AASHTO LRFD

Mar Mac Polyseal Pipe Coupler Product Sheet

N-12 & HP Storm: Corrugated Dual Wall Pipe Comparison

N-12 Mega Green (per ASTM F2648) ST IB Pipe Product Sheet

N-12 Plain End (AASHTO) Product Sheet

N-12 ST IB (per AASHTO) Product Sheet

N-12 ST IB (per ASTM F2648) Product Sheet

N-12 WT IB (per AASHTO) Product Sheet

N-12 WT IB (per ASTM F2648) Product Sheet

Potato Pipe Rotation Schedule Sheet

Rainwater Harvesting with HDPE Pipe Cisterns Product Sheet

Site Development Solutions Brochure

Small Diameter N-12 Pipe & Fittings Brochure

Corrugated Plastic Pipe Storm Installation Manual (Pocket Guide)

HDPE Pipe Installation for Agricultural Drainage Installation Guide

N-12 Flex Pipe Installation Guide

N-12® HDPE (per AASHTO) Pipe for Agricultural Drainage Installation Guide

N-12® HDPE (per ASTM F2648) Pipe for Agricultural Drainage Installation Guide

S1.01 N-12 ST IB (ASTM F2648) Specification

S1.02 N-12 WT IB (per ASTM F2648) Specification

S1.03 N-12 ST IB (per AASHTO) Specification

S1.04 N-12 WT IB Pipe (per AASHTO) Specification

S1.05 N-12 Mega Green ST IB Specification

S1.06 N-12 Mega Green WT IB Specification

S1.07 ADS N-12 WT Series 35 Pipe Specification

S1.09 N-12 Plain End (per AASHTO) Specification

S1.11 Retention/Detention Pipe System Specification

S4.05 Flared End Section Specification

S4.06 Mitered End Section Specification

S4.07 Taylor End Plug Specification

TN 1.01 Dual Wall HDPE Pipe Perforation Patterns

TN 2.01 Minimum Maximum Cover Heights for HDPE per AASHTO

TN 2.02 Minimum and Maximum Cover Heights for HDPE per ASTM F2648

TN 5.02 Flowable Fill Backfill for Thermoplastic Pipe

TN 5.04 HDPE and HP Storm Connections to Manholes and Structures

TN 5.06 Culvert Sliplining with HDPE Pipe

TN 5.07 Post-Installation Testing for HDPE Pipe

TN 5.09 Thermoplastic Pipe and Utility Crossings

TN 5.10 Integral Bell Transition for HDPE Pipe

TN 5.11 Sliplining Extended Lengths with HDPE Pipe

TN 5.16 Methods for Sealing Vent Tubes

N-12 Dual Wall Case Studies

N-12 Dual Wall Case Studies

Watch how the scale and power of ADS continues to evolve and revolutionize stormwater management.

Case Studies